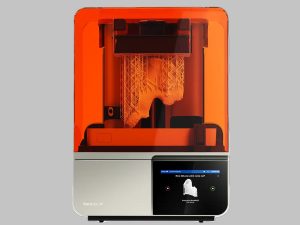

Formlabs, a leading 3D printing company valued at $2 billion, has launched its latest innovation: the Form 4 3D printer. This cutting-edge printer, already in use at major corporations like Microsoft, Ford, and NASA, marks a significant advancement in the world of additive manufacturing.

The Form 4 printer boasts impressive capabilities, with the ability to produce up to 400 models per hour while requiring only 15 minutes of training for users. According to Formlabs CEO Max Lobovsky, the printer sets a new standard for accuracy and ease of use, as confirmed by beta testers at prominent companies.

What sets the Form 4 apart is its incorporation of 3D printed parts into its own design, highlighting the printer's innovative approach to manufacturing. Previous generations of Formlabs printers, such as the Form 3+, have contributed to various applications, including bottle designs at Unilever and customized toys from Hasbro.

At Ford, the Form 4 is instrumental in producing manufacturing aids for cars, while dentists utilize it to create patient retainers. Microsoft has designated the Form 4 as its "go-to" for engineering projects, citing its exceptional output and speed.

Formlabs faces competition from industry players like BigRep, Shapeways, and Markforged. However, the Form 4's performance and capabilities have garnered praise from major companies, including consumer product firm OXO.

The launch of the Form 4 comes at a time of exponential growth in the 3D printing market, which was valued at $22 billion in 2023 and is projected to reach $150 billion by 2032. Entrepreneurs seeking to enter the 3D printing space have various options, with affordable models like the Bambu Lab X1 Carbon and the Prusa MK4 offering impressive printing capabilities.

The Form 4 is now available for purchase through Formlabs, with packages starting at $4,500 and going up to $8,700. Its commercial availability signals a new era in 3D printing, with the potential to revolutionize industries ranging from automotive to healthcare.

The Form 4 3D printer represents a significant milestone in additive manufacturing technology. With its unmatched speed, accuracy, and ease of use, it has the potential to expand the applications of 3D printing beyond prototyping to mass-produced consumer goods. As companies continue to adopt this groundbreaking technology, the future of manufacturing looks increasingly innovative and promising.